Advance of construction of 14 dwellings in Sant Ferran, Formentera

We’ve finished the works!

May 6, 2014

>Verification of the document readiness for construction and start of works.

May 7, 2014

>Visit to the collection of Posidonia on the beach of Ca Marí and pallets in the transfer center Cap de Barbaria and facilities Ferrovial Agroman.

May 8, 2014

>Beginning of demolition work, soil tastings and protection of existing juniper.

May 12, 2014

>Beginning of the excavation.

June 9, 2014

>Start of the pouring of the first tier of NHL-5 lime concrete foundation (in total 3 tiers 17cm will be made).

7/8 July 2014

>Collection of 400m³ of neptune grass at Ca Marí beach by the Environmental Area of the Consell de Formentera, and transportation and storage at the transfer center Cap de Barbaria.

August-September 2014

>Neptune grass drying process.

September-decembre 2014

>Lime concrete NHL-5 foundations have been completed.

January 2015

>The first foundation walls have been raise. They are made of concrete blocks armed with galvanized Murfor bars as an alternative to in-situ concrete wall.

February 2015

>The first floor has been made of the prefabricated YTONG cell concrete slabs.

>The first YTONG cellular concrete walls have been raised. All waste generated is collected to be used as light filling between slabs.

>We initiate first contacts with local fishermen to collect fishing nets that are discarded in October. The nets will be used as façade support for climbing plants with sun protection function.

March 2015

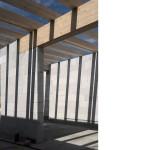

>Placement of the first laminated-wood beams.

The heads are wrapped in reused cardboard from packaging, so the heads are permanently ventilated.

We remind that only have been treated with biocide the inaccessible parts of the wood (heads, etc.) and wet areas (bathrooms and kitchens).

>HDPE waterproof sheets have been placed on the foundation, as an alternative to PVC or asphalt derivatives.

>8 samples of NHL-5 lime concrete pavements have been made including reused aggregates from own excavation of earthen color, in order to be tested.

April 2015

>The first wood roofs have been finished!

>The water tanks marès stone vaults have been finished. This system has been chosen as an alternative to the armed concrete structures, since the humid environment damages it. The stone vault will provide a higher durability of the construction, so the life cycle is better.

>The stone was brought from Cas Busso quarry, in Mallorca, since there are no longer active quarries in Ibiza and Formentera.

>The first walls between plots have been raised. They are made of H-16 ceramic block cooked in traditional Moorish ovens fed with biomass, at Can Mascaró tile factory, in Vilafranca.

>It should be noted that this type of factories have only survived in the Balearic Islands, since industrial production led to the disappearance of them in Spain. Therefore, they are nowadays the only tile factories powered by 100% renewable energies throughout the Spanish state.

May 2015

>Neptune grass drying process, season 2!

June 2015

>The image of Formentera’s boat shacks reminds us about the time when reusing was the ONLY way forward, and it motivates us to look again unforeseen waste.

We’ve initiated first contacts between IBAVI and Deixalles Foundation, and discovered old northern pine planks from abandoned mattress which will be reused for the realization of vertical slats blinds on ground floor.

>The polycarbonate sliding doors insulated with Posidonia will be replaced by second hand windows, allowing the user to have a transparent or opaque closing, according to the needs of each moment.

>All the opaque interior doors are replaced with reused doors. Those similar to the project (72cm) are placed as hinged door. In case of exceeding 78cm are placed sliding.

July-august 2015

>A compromise between IBAVI and Deixalles Foundation has been arranged for reusing 2nd hand joinery, which will be used exclusively indoors.

The Deixalles Foundation is a non-profit organization whose main objective is the social and labor inclusion of vulnerable groups through recovery and recycling and environmental activities in general.

>The Deixalles Foundation will give up the woodwork at a special price, and the IBAVI will disseminate the results of this exceptional collaboration by using the resources defined at the LIFE Project Communication Campaign, explaining that this reuse provides the following benefits:

1. Use of premium woods (old northern pine, old Douglas fir, etc.), generally over 50-70 years old, which guarantees the natural tree growth and a process of drying which is inaccessible today, and therefore they become unique objects and a very useful way of working to be included in architecture in general.

2. Raw-materials exploitation reduction.

3. CO2 emissions reduction during manufacture of the woodwork.

4. Waste generation reduction.

>Please check Joinery wood (FSC or PEFC seal or reused) section to know more about it.